CNC na musamman graphite farantin

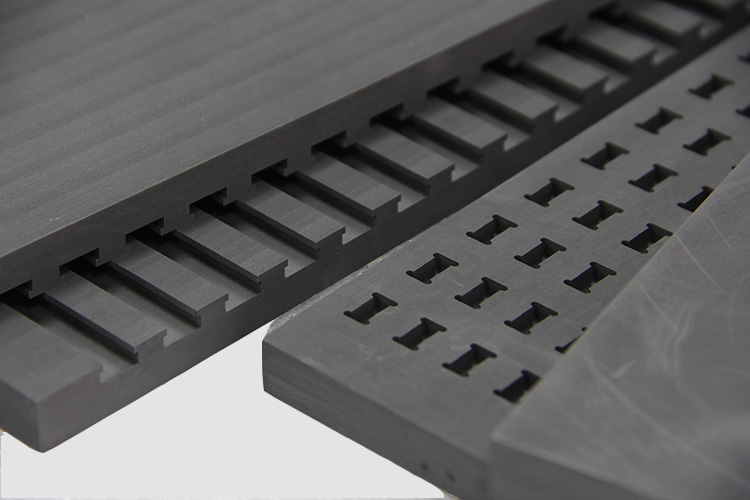

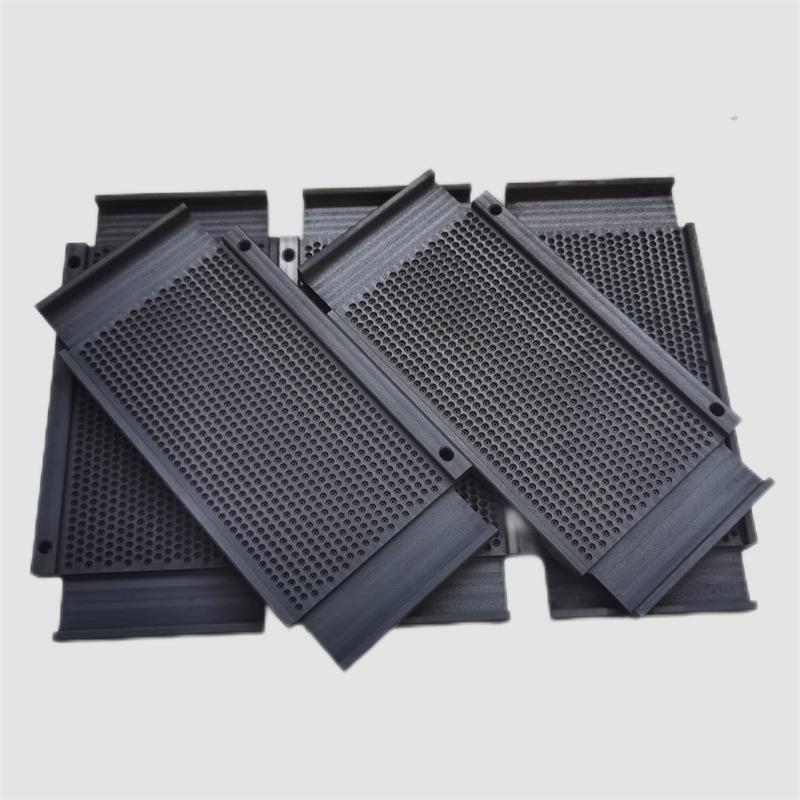

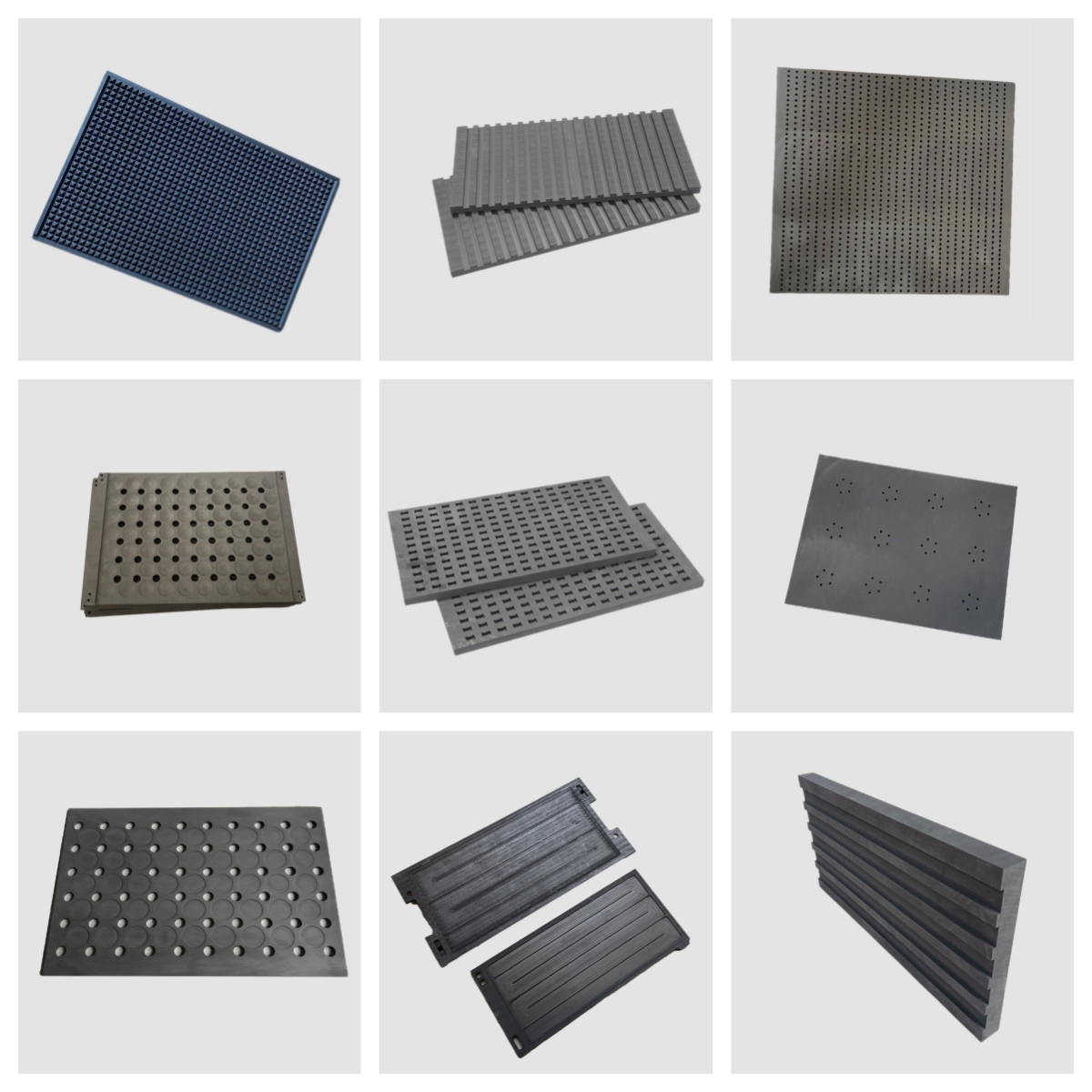

Siffofin

1) Kayayyakin da za a iya jujjuyawa: A cikin masana'antar narkewa, ana amfani da faranti na graphite don kera crucibles na graphite, a matsayin wakilai masu kariya don ingot ɗin ƙarfe, da kuma bulo na magnesia na carbon don rufin murhun wuta.

2) Kayan aiki: A cikin masana'antar lantarki, ana amfani da graphite sosai azaman na'urorin lantarki, goge, bututun carbon, da sutura don bututun talabijin.

3) Saka resistant kayan da man shafawa: A da yawa inji kayan aiki, graphite faranti ana amfani da matsayin lalacewa resistant da lubricating kayan, wanda zai iya zamewa a gudun 100m / s a cikin zafin jiki kewayon -200 zuwa 2000 ℃ ba tare da ko tare da kadan amfani. man shafawa.

4) Seling abu: Yi amfani da m graphite kamar piston zobe gaskets, sealing zobba, da dai sauransu ga centrifugal farashinsa, ruwa turbines, turbi turbi, da kuma kayan aikin kai lalata kafofin watsa labarai.

5) Lalata resistant abu: Yin amfani da graphite faranti a matsayin tasoshin, bututun, da kuma kayan aiki, zai iya jure da lalata na daban-daban m gas da kuma taya da aka yi amfani da ko'ina a sassa kamar man fetur, sinadaran, da kuma hydrometallurgy.

6) Thermal rufi, high-zazzabi juriya, da radiation kariya kayan: Graphite faranti za a iya amfani da matsayin neutron moderators a cikin nukiliya reactors, kazalika da nozzles, hanci cones, Aerospace kayan sassa, thermal rufi kayan, radiation kayan kariya, da dai sauransu.

1. Kyakkyawan isotropy, halaye masu zaman kansu na girman, siffar, da jagorancin samfurin;

2. Tsarin Uniform, yawa, da ƙarfin antioxidant mai ƙarfi;

3. Kyakkyawan lubrication kai;

4. Kyakkyawan juriya ga lalata sinadarai;

5. High thermal conductivity da thermal kwanciyar hankali yi;

6. Ingantacciyar ƙarfin injiniya da juriya mai tasiri;

7. Mai sauƙin na'ura kuma ana iya sarrafa shi zuwa nau'ikan geometric daban-daban bisa ga buƙatu.

Lokacin amfani da sabon famfo, kula da alkiblar motar kuma ka guji haɗa shi don juyawa kayan aiki.Juyawa juyi na tsawon lokaci na famfo zai lalata ruwan wukake.

Yawan ƙura a wurin aikin famfo da rashin isassun tace iska na iya ƙara lalacewa da kuma rage tsawon rayuwar ruwa.

Mahalli masu danshi na iya haifar da lalata a kan ruwan wukake da bangon ramin rotor.Lokacin fara famfo na iska, abubuwan da ke cikin ruwan bai kamata a jefa su waje ba, saboda rashin daidaituwa na iya lalata ruwan wukake.A irin waɗannan lokuta, ya kamata a duba ruwan wukake kuma a fara tsaftace su.

Sauyawa akai-akai yayin amfani da famfo yana ƙara yawan tasiri yayin fitar da ruwa, yana rage tsawon rayuwar ruwan wukake.

Rashin ingancin ruwa na iya haifar da raguwar aikin famfo ko lalacewa ga ganuwar Silinda, don haka ya kamata a kauce masa.

1. Ƙarfin sarrafawa mai ƙarfi, mai iya samar da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun graphite.

2. Za mu iya samar da graphite kayayyakin for extrusion gyare-gyare, vibration gyare-gyare, gyare-gyaren, da kuma isostatic latsa gyare-gyare kamar yadda ake bukata.

3. Dangane da buƙatun fasaha daban-daban, samfuran graphite irin su faranti na graphite za a iya fuskantar jiyya na juriya na iskar shaka, jiyya mara ƙarfi, da jiyya na ƙarfafawa don haɓaka aikin su da rayuwar sabis.