Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

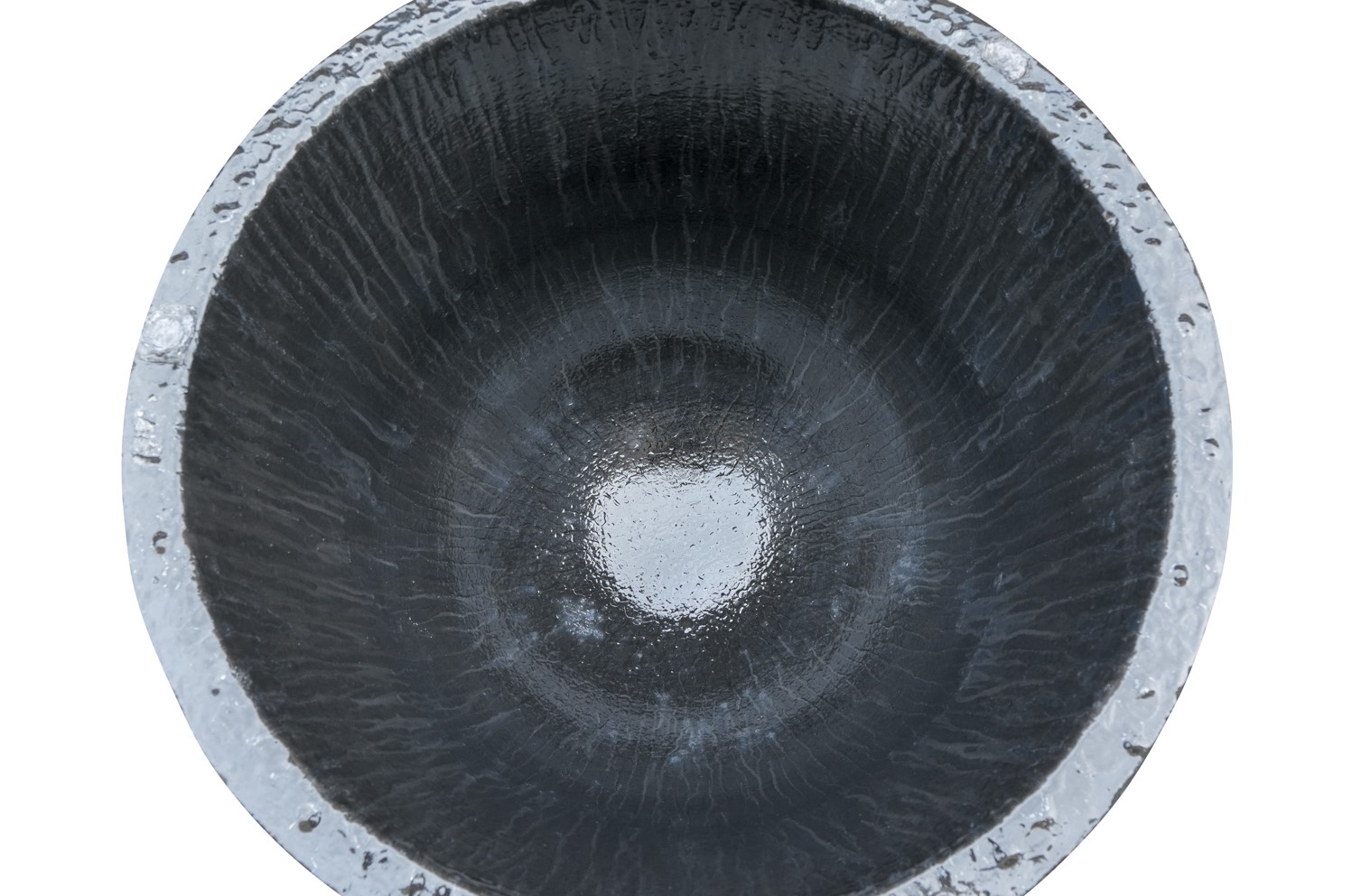

Ƙarfe Mai Narke Crucible Aluminum don Yin Cast

SIFFOFIN KIRKI

Narkewar gaggawa

High thermal conductivity graphite abu inganta thermal yadda ya dace da 30%, muhimmanci rage narkewa lokaci.

Maɗaukakin Ƙarfafa Ƙwararru na Thermal

Fasaha mai haɗawa da guduro tana jure wa saurin dumama da sanyaya, tana ba da damar yin caji kai tsaye ba tare da tsagewa ba.

Dorewa Na Musamman

Ƙarfin injina yana tsayayya da tasirin jiki da yazawar sinadarai don tsawon rayuwar sabis.

BAYANIN FASAHA

| Graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Girman girma / g·cm⁻³ | 2.20 |

| Bayyanar porosity / % | 10.8 |

| Ƙarfin murƙushewa / MPa (25 ℃) | 28.4 |

| Modulus na rupture/MPa (25 ℃) | 9.5 |

| Yanayin juriya na wuta / ℃ | > 1680 |

| Thermal girgiza juriya / Times | 100 |

| No | Samfura | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| Saukewa: RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| Saukewa: RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| Farashin RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| Farashin RR351 | 351# | 650 | 420 | 230 |

TSARI ZUWA

1. Daidaitaccen Tsari

Babban tsaftar graphite + silikon carbide mai ƙima + wakili mai ɗaure.

.

2.Isostatic Pressing

Yawaita har zuwa 2.2g/cm³ | Hakurin kaurin bango ± 0.3m

.

3.High-Temperature Sintering

SiC barbashi recrystallization kafa 3D tsarin cibiyar sadarwa

.

5.Ingantacciyar Ingancin Inganci

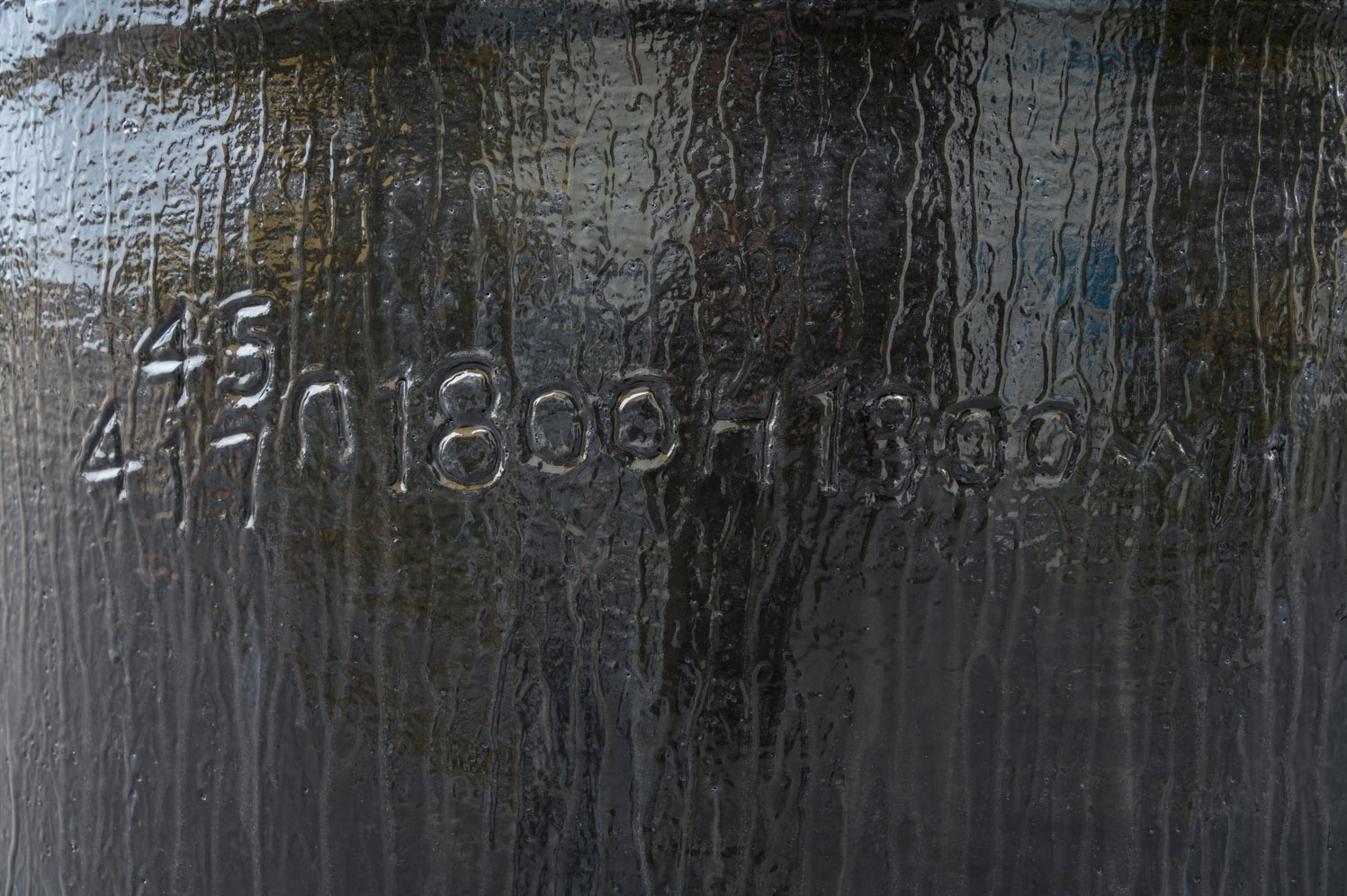

Lambar bin diddigi na musamman don cikakken gano yanayin rayuwa

.

4. Fannin Ingantawa

Anti-oxidation shafi → 3× inganta lalata juriya

.

6.Kunshin Tsaro

Layer mai shayar da girgiza + Katanga mai danshi + Ƙarfafa murfi

.

APPLICATION KYAUTA

Ya dace da yawancin karafa marasa ƙarfe

Narke Aluminum

Narke Copper

Narke Zinariya

ME YASA ZABE MU

FAQS

Q1: Shin Rufin Crucible zai iya rage farashin makamashi?

A: Lallai! Yana rage asarar zafi, yanke amfani da makamashi har zuwa 30%.

Q2: Wadanne murhun wuta ne suka dace?

A: Yana da nau'i-nau'i-ya dace da shigarwa, gas, da tanderun lantarki.

Q3: Shin graphite silicon carbide lafiya ga high yanayin zafi?

A: iya. Tsawon yanayin zafi da sinadarai ya sa ya zama cikakke ga matsanancin yanayi.

Q4: Yadda za a hana crucible cracking?

Kada a taɓa yin cajin kayan sanyi cikin maɗaurin zafi (max ΔT <400°C).

Yawan sanyaya bayan narkewa <200 ° C / awa.

Yi amfani da ƙwanƙolin ƙirƙira (kauce wa tasirin injina).

Q5: Yadda za a hana crucible cracking?

Kada a taɓa yin cajin kayan sanyi cikin maɗaurin zafi (max ΔT <400°C).

Yawan sanyaya bayan narkewa <200 ° C / awa.

Yi amfani da ƙwanƙolin ƙirƙira (kauce wa tasirin injina).

Q6: Menene mafi ƙarancin tsari (MOQ)?

Standard Model: guda 1 (samfurori akwai).

Tsare-tsare na Musamman: guda 10 (ana buƙatar zane na CAD).

Q7: Shin kuna da ƙwararrun ƙungiyoyin ƙwararru?

Kamfaninmu yana alfahari da babban fayil na takaddun shaida da alaƙa a cikin masana'antar. Wannan ya haɗa da takaddun shaida na mu na ISO 9001, wanda ke nuna sadaukarwarmu ga gudanarwa mai inganci, da kuma kasancewar mu a cikin ƙungiyoyin masana'antu da yawa masu daraja.

Q8: Menene graphite carbon crucible?

Graphite carbon crucible ne crucible tsara tare da high thermal watsin abu da kuma ci-gaba isostatic latsa gyare-gyaren tsari, wanda yana da ingantaccen dumama iya aiki, uniform da m tsari da kuma m zafi conduction.

Q9: Me zai faru idan kawai ina buƙatar ƴan siliki carbide crucibles kuma ba adadi mai yawa ba?

Za mu iya cika umarni na kowane adadi na siliki carbide crucibles.

Nazarin Harka #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Karatun Harka #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Shaida

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id celerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id celerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe