Idan ya zo ga sarrafa zafin jiki, sintering, maganin zafi da haɓakar karafa, yumbu da sauran kayan, zaɓi of buguyana taka muhimmiyar rawa. Crucibles sune mahimman tasoshin da aka yi amfani da su a cikin matakai daban-daban na masana'antu, kuma zabar madaidaicin kayan da aka yi amfani da shi zai iya tasiri sosai ga tasiri da sakamakon waɗannan matakai. A cikin wannan gabatarwar samfurin, za mu bincika bambance-bambance tsakanin silicon carbide da graphite crucibles, mai da hankali kan halayensu na musamman, rayuwar sabis, farashi, da kewayon aikace-aikace.

Silicon carbide crucible:

Silicon carbide crucibles an yi su ne da kayan siliki na siliki, wanda aka sani da kyakkyawan yanayin juriya da juriya na lalata. Wadannan crucibles ana amfani da ko'ina a high-zazzabi sintering, zafi magani da crystal girma tafiyar matakai na karafa, tukwane da sauran kayan. Ƙaƙƙarfan ƙaƙƙarfan kaddarorin silicon carbide sun sa ya dace don aikace-aikace inda matsananciyar yanayin zafi da lalata muhalli suka zama ruwan dare. Duk da haka, ya kamata a lura cewa idan aka kwatanta da graphite crucibles, silicon carbide crucibles suna da ɗan gajeren rayuwar sabis, musamman ma a ƙarƙashin yanayin zafi da lalata. Halin siliki carbide crucibles don oxidize da ablate zai shafi rayuwar sabis ɗin su. Ko da yake silicon carbide crucibles suna da ɗan gajeren rayuwar sabis, suna da mahimmanci a cikin masana'antu waɗanda ke buƙatar sarrafa abubuwa masu lalata da zafi sosai, yana mai da su zaɓi na farko don aikace-aikacen masana'anta na lantarki da na optoelectronic.

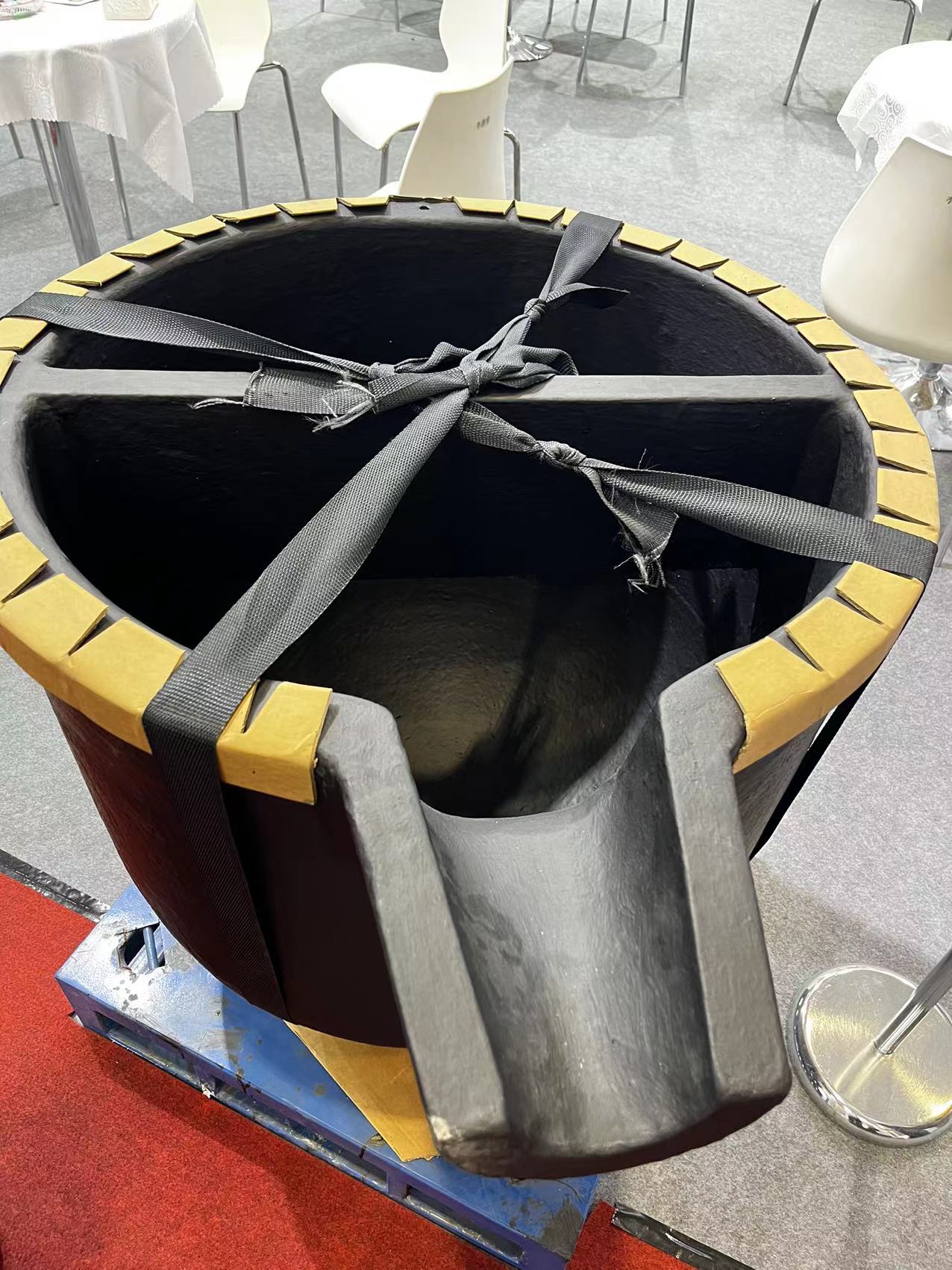

Graphite crucible:

Akasin haka, graphite crucibles an yi su ne da kayan graphite kuma ana amfani da su sosai wajen sarrafa kayan ƙarfe da waɗanda ba na ƙarfe ba. Graphite crucibles an san su da kyakkyawan juriya ga hadawan abu da iskar shaka, ablation da zafin jiki mai yawa, wanda ke haifar da rayuwar sabis mai tsayi sosai idan aka kwatanta da siliki carbide crucibles. Wannan ɗorewa yana sa graphite crucibles ya zama zaɓi mai inganci don aikace-aikacen da suka shafi maganin zafi da haɓakar ƙira na kayan iri-iri. Samar da araha na crucibles graphite, haɗe tare da tsawon rayuwarsu na sabis, ya sa su zama mashahurin zaɓi ga waɗancan masana'antu waɗanda ke neman abin dogaro da dorewa a cikin tsarin sarrafa su.

Zaba madaidaicin ƙugiya:

Zaɓin tsakanin silicon carbide da graphite crucibles a ƙarshe ya dogara da takamaiman buƙatun aikace-aikacen. Ko da yake siliki carbide crucibles suna da kyakkyawan juriya ga yanayin zafi da lalata, sun fi tsada saboda hanyoyin masana'antu da farashin kayan. Graphite crucibles, a gefe guda, sun fi tattalin arziki, suna da tsawon rayuwar sabis, kuma sun dace da aikace-aikace iri-iri, musamman waɗanda suka shafi sarrafa kayan gabaɗaya, maganin zafi, da haɓakar crystal.

A takaice dai, siliki carbide crucibles da graphite crucibles suna da nasu amfani da rashin amfani. Lokacin zabar crucible don takamaiman aikace-aikacen, takamaiman yanayin aiki, buƙatun kayan aiki, da ƙuntatawa na kasafin kuɗi dole ne a yi la'akari da su. Don matsanancin zafin jiki, sarrafa kayan abu mai lalata sosai, ko masana'anta a cikin kayan lantarki da filayen optoelectronics, siliki carbide crucibles shine zaɓi na farko. Sabanin haka, don maganin zafi da haɓakar kristal na kayan yau da kullun, ƙwanƙwasa graphite suna ba da mafita mai tsada da dorewa.

A [sunan kamfanin ku], muna ba da cikakken kewayon crucibles carbon graphite crucibles, graphite crucibles, silicon carbide graphite crucibles da silicon graphite crucibles don saduwa da daban-daban masana'antu bukatun. An tsara kullun mu zuwa mafi girman matsayi, yana tabbatar da aiki mafi kyau da aminci a cikin matakai daban-daban na masana'antu. Ko kuna buƙatar crucibles don zafin jiki mai zafi, magani mai zafi ko haɓakar kristal, kewayon samfuran mu yana ba da ƙwaƙƙwarar ƙarfi da dorewa da ake buƙata don tallafawa aikin ku.

Zaɓi [Sunan Kamfanin ku] don ƙwanƙwasa masu inganci tare da keɓaɓɓen aiki da rayuwar sabis, yana ba ku damar cimma kyakkyawan sakamako a cikin ayyukan masana'antar ku. Tuntube mu a yau don bincika cikakken kewayon mu na crucibles kuma nemo cikakkiyar mafita don takamaiman buƙatun ku.

Lokacin aikawa: Maris 27-2024