Akwai mahimman bambance-bambance tsakaninCarbide curbideKuma gizagizai mai zane a cikin fannoni da yawa kamar kayan, tafiyar matakai, da farashin. Waɗannan bambance-bambance ba kawai ke shafar tsarin masana'antar masana'antu ba, har ma suna ƙayyade tasirinsa da kuma aikace-aikacen aikace-aikace.

Babban bambanci

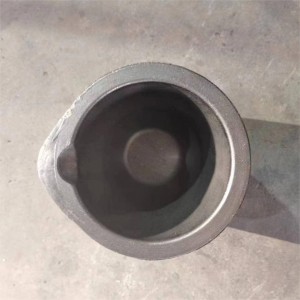

Yawancin gizagizai masu zane-zane ana yin su ne da flake zane mai zane da kuma amfani da yumɓu a matsayin mai ban sha'awa. Haɗin wannan hade yana ba da tsayayyen yanayin da ake cutar da zafin jiki da juriya da zazzabi, sa ya dace da aikace-aikace a cikin matakai masu yawan sanyi. Tsarin na musamman da kuma babban aikin zafi na dabi'a flake zane mai zane ya yi matukar farin jini sosai a cikin ƙarfe da masana'antu masu kafa.

Silicon Carbide Cruciible ya dogara da zane mai zane mai zane, tare da silicon carbide kamar yadda babban bangaren da high zazzabi a matsayin mai masarufi. A matsayina na Silnhard abu, Carbide Carbide sosai sanye da juriya da kwanciyar hankali, ba da damar silicon carbibille curcide a cikin more more m. Amfani da high-zazzabi resin shima yana inganta ƙarfin da aka gicciye da tsoratarwa.

Aiwatar da bambance-bambance

Tsarin masana'antar na gurbataccen hoto galibi ya dogara da latsa da injiniya. An kafa karamin karfi na murɗa zane-zane gaba daya, sannan kuma an yiwa tsoka a cikin babban zazzabi na digiri 1,000, kuma a ƙarshe mai rufi tare da anti-corrose don kara tsoratarwa da juriya-orrosion fenti don kara tsaurara da juriya. Wannan tsari na gargajiya, yayin da tsada-tsada, yana da iyakoki dangane da ingancin samarwa da daidaiton daidaito.

Tsarin samarwa na silicon Carbide Crucide ne ya ci gaba, ta amfani da kayan latsa kayan aiki da tsarin kimiyya. Fasahar latsa tana amfani da matsanancin matsin lamba (har zuwa MPA 150), sakamakon shi sosai da yawa da daidaito a cikin mai iya bakin ciki. Wannan tsari ba wai kawai yana inganta ƙarfin ƙarfin da aka gicciye ba, har ma yana da matukar tasiri sosai ga rawar jiki da lalata.

Bambance bambance bambance-bambance

Dangane da batun aiki, akwai bambance-bambance masu mahimmanci tsakanin giciye na zane da silicon carbide curbibles. Murmushi mai zane suna da yawa na 13 Ka / cm², yayin da silicon carbibless da yawa na 1.7 zuwa 26 Ka / MM². Rayuwar sabis na giciye na zane-zane yawanci sau 3-5 ne na silicon carbide curcibless, wanda shine yawanci saboda karfi na kayan silicon curbide crucible.

Bugu da kari, Bambancin zazzabi tsakanin ciki da waje na mai zane mai zane shine kimanin digiri na 5-5, yayin da digiri na silicon carbide ne kawai sau biyu cikin sharuddan sarrafa zazzabi da kwanciyar hankali. A acid da alkalim juriya da lalata cututtukan silicon carbide cirewa kuma ya fi karfin makamashi kusan kashi 50% fiye da crucible karfi.

Bambanci a farashin

Saboda bambance-bambance a cikin kayan da masana'antu, giciye mai zane da silicon carbide curbides sniple su kuma suna da mahimmancin farashin farashi. Yawanci, carbide curbide curucils kusan sau uku sun fi tsada fiye da gurbataccen hoto. Wannan bambancin farashin yana nuna babban fa'idodin silicon carbide curcilbilbles dangane da farashin kayan, masana'antu tsari da aiki.

In summary, although silicon carbide crucibles cost more, their superior durability, corrosion resistance, and energy efficiency make them a more cost-effective choice for many demanding applications. Mummunan zane-zane na ci gaba da amfani da su a aikace-aikace na gargajiya da yawa saboda ƙananan farashin su da kyawawan kaddarorin su. Abokan fa'idodi da kuma rashin amfanin wadannan giciye guda biyu suna tantance su sun dace da yanayin aikace-aikace daban.

Lokaci: Jun-13-22